HDPE Pipes

Advanced HDPE Pipe Solutions by Anaconda Pipe and Hose

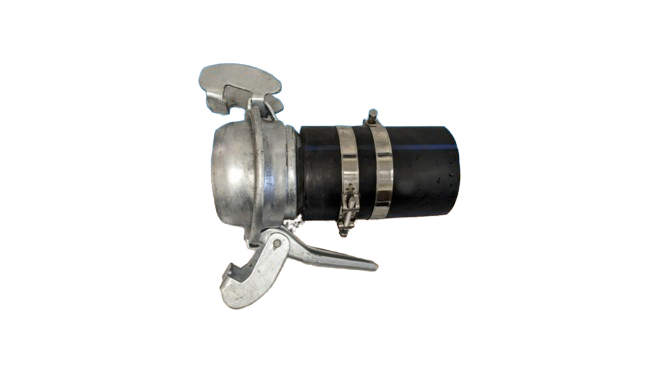

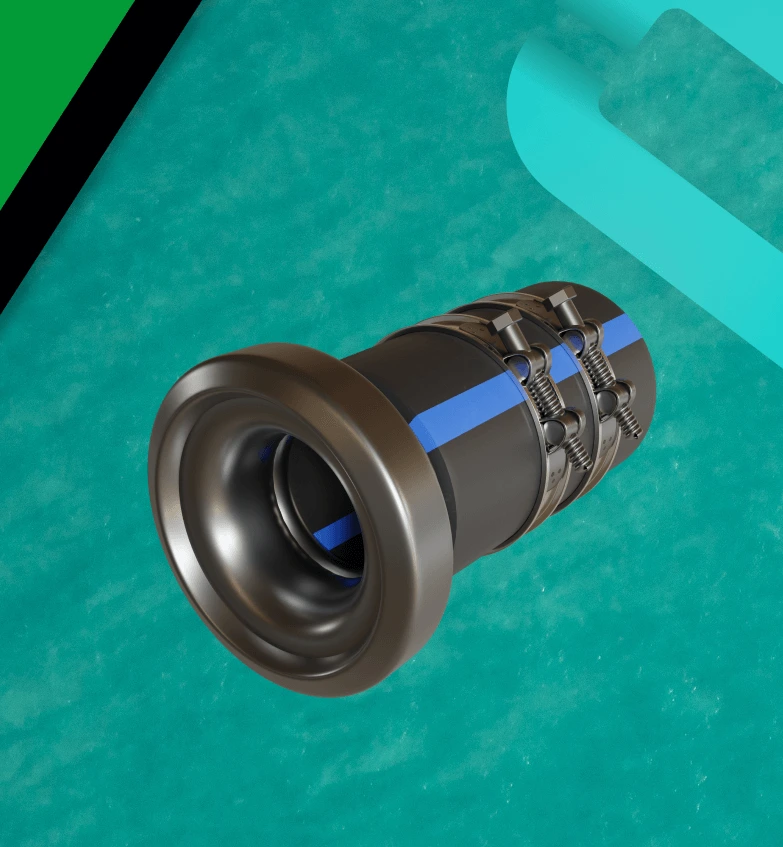

Innovative Bauer Couplings

Anaconda HDPE pipes come equipped with Bauer couplings known for their versatility and cost-effectiveness. These modular fittings allow for quick and easy adjustments, significantly reducing the time and labor involved in connecting and disconnecting pipes.

Comprehensive Thickness Options

Anaconda offers HDPE pipes in three thickness grades: DR11, DR17, and DR26. This range ensures that you can choose the ideal pipe for your project’s requirements, providing enhanced performance across various applications.

Flexible Rent or Purchase Options

Anaconda Pipe & Hose stands out as one of the few North American manufacturers offering both rental and purchase options for HDPE pipes. This flexibility allows customers to manage costs more effectively, with rental solutions available for short-term projects (specific terms apply).

Tailored Customization

Anaconda provides extensive customization options for its HDPE pipes, allowing clients to specify the diameter, length, and material composition. This customization ensures that each pipe meets precise industrial needs.

Versatile Industrial Applications

Engineered for a wide range of uses, Anaconda HDPE pipes are ideal for fluid transportation, chemical handling, and supporting various industrial fluid systems. Their durable construction ensures reliable performance in demanding environments.

Seamless Fitting Integration

Designed to work with a variety of fitting types, Anaconda HDPE pipes connect seamlessly to threaded connections, Bauer fittings, ANSI flanges, and other couplings, ensuring leak-proof and durable installations.

As the authorized distributor in Jamaica, Pumps For Jamaica is proud to offer Anaconda Pipe and Hose’s high-quality HDPE pipe solutions, delivering innovative and reliable products to meet the needs of your industrial projects.

Ready to Streamline Your Piping System?

Experience the benefits of using straight HDPE pipe lengths without fittings for your next project. Enjoy improved flow efficiency, lower maintenance requirements, and easier installation. Contact our experts today to learn how our HDPE solutions can be tailored to meet your needs and boost your operational efficiency.

Engineered for Industrial Excellence

Anaconda Pipe & Hose’s industrial HDPE pipes stand out for their easy connection and disconnection capabilities, featuring Bauer fittings that enhance modularity and enable quick adjustments to suit changing project needs. Constructed from high-quality materials, these pipes are built for durability and are capable of withstanding harsh environments thanks to their high-pressure tolerance and temperature resistance. Their exceptional corrosion resistance, achieved through protective coatings, extends the pipes’ lifespan and ensures reliable performance in corrosive settings.

Anaconda HDPE pipes are precision-engineered for exact dimensional accuracy, facilitating seamless integration with various fittings and minimizing the risk of leaks. They strike an ideal balance between flexibility for versatile installation options and rigidity to maintain structural integrity under operational stress. Rigorous quality assurance processes, including thorough testing and compliance with industry standards, demonstrate Anaconda’s commitment to delivering reliable and robust piping solutions for a wide range of industrial applications.

Bauer Fittings: Elevating Industrial Pipe Systems

Bauer fittings, renowned for their quick-connect capabilities, play a vital role in industrial pipe systems across sectors like wastewater management, irrigation, construction, and mining. Also known as Bauer couplings, these fittings provide rapid, secure connections that minimize downtime and ensure leak-free operation, enhancing system reliability and environmental safety.

The adaptability of Bauer fittings makes them suitable for various pipe materials and sizes, offering a versatile solution for diverse fluid transport needs. Made from durable materials such as galvanized or stainless steel, they are built to withstand demanding industrial conditions, providing a long service life and reducing the frequency of replacements. The fittings’ reliable sealing mechanism ensures a tight, leak-proof connection for a wide range of fluids, including harsh chemicals and slurries, while their pressure adaptability accommodates different pressure levels.

Bauer fittings are also user-friendly, featuring a quick-locking mechanism that simplifies pipe system management and boosts efficiency. Their compatibility with different brands and materials adds system flexibility, making maintenance and repairs easier without the need for welding or pipe fusing. This ease of use, combined with their low maintenance requirements and cost-effectiveness, makes Bauer fittings a top choice for companies seeking reliable and safe fluid handling solutions. A variety of accessories further enhances their functionality, allowing for customization to meet the specific demands of each application.

The Advantages of Using Straight HDPE Pipe Lengths Without Fittings

In many industrial applications, opting for straight lengths of HDPE pipes without fittings can provide significant technical and operational benefits. This choice enhances fluid system efficiency by creating a smoother flow path. Without the abrupt directional changes caused by fittings, friction, and turbulence are reduced, leading to better flow dynamics and overall system performance.

Using straight pipe lengths also simplifies both maintenance and installation. With fewer components to potentially fail or wear out, maintenance is less frequent and more straightforward, which helps to reduce long-term costs and minimize operational disruptions. Additionally, the installation process becomes more efficient, as straight lengths are easier to handle, align, and install, which can significantly cut down on labor costs and time, particularly in large piping networks.

The continuous nature of straight lengths also improves structural integrity, which is especially important in environments where stability and resistance to external forces are critical. With fewer connections, the risk of leaks is minimized, making it ideal for systems that transport hazardous materials or require absolute leak prevention.

Choosing straight lengths can also result in cost savings, depending on the specific needs of the project. This configuration is particularly advantageous in specialized applications where the design requirements do not call for fittings due to the nature of the fluid, pressure conditions, or other system-specific factors.

However, it’s important to evaluate the suitability of this approach for each project, considering the specific requirements, industry standards, and regulatory guidelines. In cases where frequent connections or disconnections are necessary, the use of fittings such as Bauer or ANSI may offer more flexibility. Consulting with engineering experts and adhering to best practices are essential steps in determining the most appropriate piping setup for any given application.

Related Equipment

Pipes and Hoses

Pumps For Jamaica carries a wide range of resilient pipes and hoses designed to withstand extreme conditions and deliver reliable performance across a variety of industrial applications. Our products are available in various diameters and mounting styles, ensuring you find the right solution for your fluid transportation needs. With a focus on durability and efficiency, our pipes and hoses are built to last, helping you minimize maintenance costs and maximize operational uptime in tough environments.