Sludge pumps are the unsung workhorses behind some of the toughest industrial and municipal challenges, the movement and management of high-solid waste. Whether it’s pumping abrasive mining tailings, thick refinery sludge, or viscous biosolids in wastewater treatment plants, these systems operate where ordinary pumps would quickly fail. In industries where downtime can cost millions and maintenance shutdowns disrupt entire operations, the performance of sludge pumps defines operational efficiency. Their ability to move dense, corrosive, and high-viscosity mixtures reliably isn’t just a matter of convenience; it’s the crux of sustainable waste handling and fluid management across sectors.

Selecting the right sludge pumps is not simply a matter of capacity; it’s a strategic investment in uptime, energy optimization, and long-term equipment reliability. Improper sizing or unsuitable materials can lead to recurring impeller wear, seal damage, and cavitation, significantly raising operational costs. Conversely, a well-chosen sludge pump ensures continuous flow, predictable performance, and reduced power draw, resulting in measurable savings for plant operators and contractors.

Across industries in Jamaica, particularly in wastewater management, bauxite mining, marine dredging, and industrial processing, sludge handling remains critical to maintaining compliance and operational efficiency. Facilities managing lagoons, treatment basins, or process tanks depend on submersible sludge pumps for continuous operation in submerged or confined spaces where manual maintenance is limited. These robust units are designed to handle high-solid concentrations without clogging, ensuring efficient material transfer in harsh environments.

For short-term projects or sudden system failures, many operations rely on sludge pump rental options to maintain productivity. Rental solutions provide access to heavy-duty sludge pumps without the capital burden of full ownership, making them ideal for project-based operations, emergency bypasses, or seasonal dredging activities. Pumps for Jamaica provides a range of sludge pumps, from submersible sludge pumps to positive displacement models, ensuring clients always have reliable solutions suited to their specific sludge composition and discharge requirements.

In high-solid applications, every component —from the impeller geometry to the material composition —plays a decisive role. By understanding the demands of different sludge types and selecting the proper pumps, operators can achieve long-term performance, minimize unscheduled downtime, and extend equipment lifespan while maintaining consistent throughput.

Analyzing Sludge Properties to Guide the Right Pump Selection

Before selecting a sludge pump, it’s essential to analyze the physical and chemical properties of the material being handled. High-solid sludge is characterized by a dense concentration of suspended particles, often exceeding 10–15% solids by weight. The type and size of these solids directly influence pump performance, efficiency, and wear rate. Fine biosludge flows more easily and can be handled by smaller centrifugal sludge pumps. In contrast, coarse dredged materials with rocks, sand, or debris require heavy-duty or submersible sludge pumps capable of passing large solids without clogging.

Abrasive and corrosive components present another critical factor. Sludge from industrial or mining operations often contains sharp mineral particles and chemically reactive compounds that can erode standard pump materials. For this reason, pumps with hardened-iron, chrome-alloy, or stainless-steel components are preferred in abrasive and chemically laden environments. Choosing pumps built with abrasion-resistant liners and impellers ensures longer service intervals and less downtime.

Viscosity also plays a vital role in determining pump type and power requirements. Thicker, non-homogeneous sludge demands higher torque and may require positive displacement or submersible sludge pumps designed for heavy-duty transfer. Conversely, thinner sludge allows for energy-efficient centrifugal pumping. Understanding these dynamics ensures the selected sludge pump aligns with the system’s hydraulic load and material properties.

Comparing thin biosludge to thick dredged slurry clearly highlights this contrast. Biosludge behaves like a semi-fluid mixture, which is easily handled by low-head pumps in wastewater facilities. In contrast, dredged slurry with high sand or silt content requires robust submersible sludge pumps that can withstand abrasive wear while maintaining flow consistency under pressure.

Beyond physical properties, chemical compatibility is equally important. The pH level and chemical makeup of the sludge determine suitable pump materials and sealing systems. Pumps exposed to acidic or caustic sludges must be equipped with corrosion-resistant alloys or specialized coatings to prevent premature degradation. Temperature variations can further affect viscosity and pump performance, emphasizing the need for carefully engineered designs.

For many operators, testing and pilot operation through sludge pump rental programs offers valuable insights before committing to a permanent installation. Renting different sludge pumps enables teams to evaluate flow behavior, head requirements, and wear patterns in real site conditions. This practical approach ensures the chosen sludge pump is both technically sound and cost-effective for long-term operation.

Ultimately, matching the pump’s mechanical and material characteristics to the sludge’s unique composition ensures reliability and performance consistency, two essential priorities for any organization managing high-solid waste efficiently and sustainably.

Comparing the Main Types of Sludge Pumps

Choosing the right type of sludge pump is critical to ensuring long-term reliability, energy efficiency, and minimal downtime in high-solid waste handling. Each pump design offers distinct advantages depending on the characteristics of the sludge, its solids concentration, viscosity, abrasiveness, and chemical properties. Understanding how these pumps work and where they perform best helps engineers and procurement teams make informed decisions for their specific applications.

Centrifugal Sludge Pumps

Centrifugal sludge pumps remain one of the most widely used options for transferring semi-fluid sludge with low to medium solids content. They operate by converting the rotational energy of an impeller into kinetic energy, generating the pressure needed to move fluid through pipelines. Their simple design, continuous operation, and compatibility with high flow rates make them a preferred choice for wastewater treatment plants, industrial effluent systems, and general process applications.

However, these pumps are most effective when handling sludge with fine or uniformly distributed solids. When particle size or density increases, the risk of impeller wear, clogging, or reduced efficiency becomes significant. For thicker or more abrasive sludge, centrifugal models may require frequent maintenance or impeller replacement. In such cases, switching to a more robust alternative, such as a submersible sludge pump or a positive displacement unit, ensures greater operational stability.

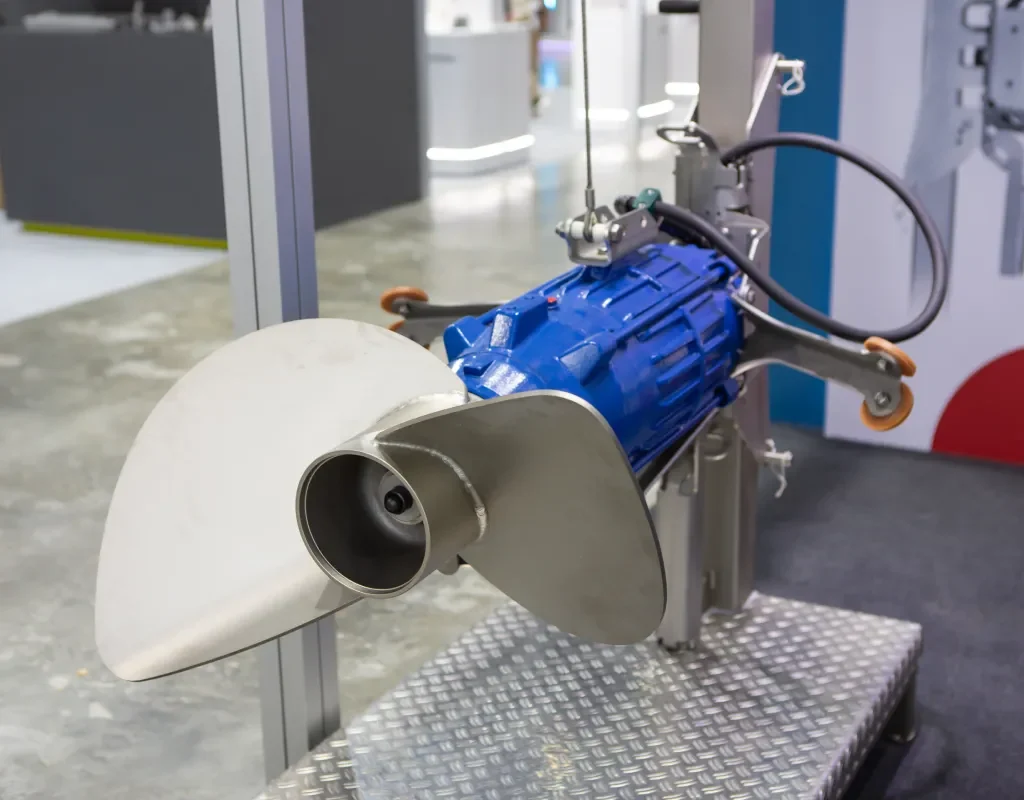

Submersible Sludge Pumps

A submersible sludge pump is ideal for confined, submerged, or flooded areas such as lagoons, sumps, tanks, and settling ponds, as it is designed to operate directly within the fluid it moves. Even under severe, abrasive conditions, dependable operation is enabled by sealing the motor and pump body to prevent fluid intrusion.

These pumps are used for construction desilting, mine dewatering, and municipal wastewater treatment due to their durability and compact size. Because submersible sludge pumps don’t need priming or suction lift like surface-mounted systems do, there is less chance of cavitation and airlock. They are ideal for applications with erratic input rates or high silt loads due to their high solids-handling capacity and continuous operation.

Operators may quickly install these submersible systems without committing to full ownership through a sludge pump rental program, which is extremely useful for emergency bypass projects or seasonal dredging operations.

Air-Operated Diaphragm (AODD) Pumps

Air-operated diaphragm (AODD) pumps offer unmatched versatility for handling sludge with varying viscosity, chemical composition, or abrasiveness. Their unique design, using reciprocating diaphragms instead of impellers, allows them to move fluids gently and without contamination. They are self-priming, dry-running capable, and explosion-proof, making them well-suited for environments with chemical exposure or limited access to electrical power.

AODD pumps excel in intermittent or batch pumping applications such as chemical processing, oil refinery sludge transfer, and industrial tank cleaning. Their portability enables rapid deployment, making them a cost-effective solution for temporary setups where sludge pump rental is preferred. Although not designed for extremely high flow rates, AODD pumps provide reliable operation where precision, safety, and flexibility are paramount.

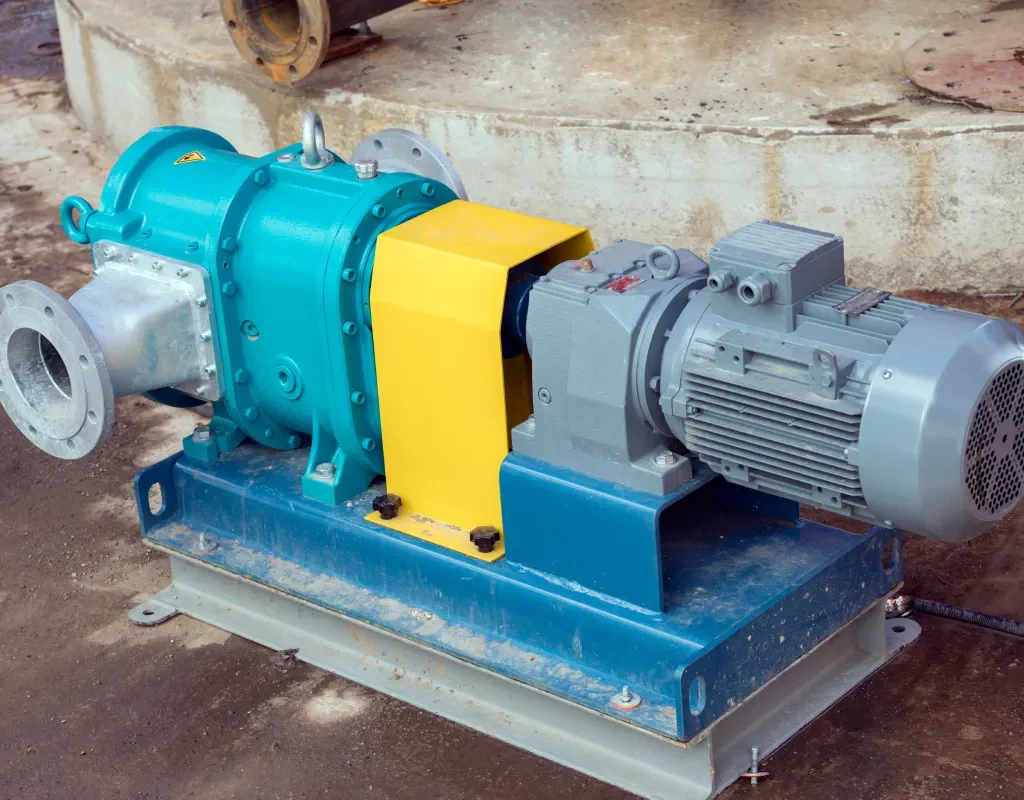

Progressive Cavity and Positive Displacement Pumps

When dealing with very viscous sludge or materials comprising big, fibrous grains, progressive cavity and other positive displacement pumps are the most efficient transfer options. These pumps circulate sludge via a series of sealed chambers, ensuring a steady flow despite pressure changes. This design reduces pulsation and mechanical shear while keeping the structure of sludge containing biological or organic components.

Progressive cavity pumps are particularly useful for wastewater treatment, food processing, and agricultural waste management, where smooth, consistent pumping is required. Their capacity to handle solids concentrations up to 40% makes them ideal for thick, non-flowing sludge, where centrifugal systems would fail. Despite increased maintenance and upfront costs, their consistent performance and resistance to clogging make them excellent for demanding, high-solidity applications.

Heavy-Duty Slurry and Industrial Pumps

Heavy-duty slurry pumps are ideal for the most harsh situations, such as mining, dredging, and large-scale industrial sludge transfer. They have the durability and power required for continuous operation. These units are designed with reinforced casings, replaceable liners, and hardened impellers to withstand heavy abrasion and prolonged exposure to corrosive substances.

Industrial-grade slurry pumps can transport thick mixtures of sand, silt, and solid-laden trash over long distances with minimal performance loss. Their heavy-duty seals and bearing systems provide reliability under severe loads, even in hostile environments. These pumps, whether used in permanent installations or mobile dredging systems, represent the pinnacle of sludge-handling technology, with unrivaled wear resistance and throughput.

Key Features to Look for in Reliable Sludge Pumps

Selecting a high-quality sludge pump goes beyond basic specifications; it requires a thorough understanding of the operational environment, the type of solids being handled, and long-term performance expectations. The right design and material choices directly determine a pump’s durability, maintenance frequency, and energy efficiency. Here are the essential features every engineer and project manager should prioritize when evaluating equipment for high-solid waste applications.

1. Clog-Resistant Passageways and Impeller Design

Reliable sludge pumps feature wide, open passageways and non-clogging impeller designs to handle solids, fibrous materials, and viscous slurries. Vortex and semi-open impellers are particularly effective in preventing blockages and maintaining consistent flow. In environments where sludge contains irregular debris, such as construction sumps or dredging sites, impeller clearance and passage width can make the difference between continuous performance and costly downtime.

2. Abrasion- and Corrosion-Resistant Materials

Because high-solid sludge often contains abrasive minerals, sand, or chemically reactive compounds, construction materials must be chosen carefully. Components made of high-chrome iron, rubber lining, or stainless steel offer superior resistance to erosion and corrosion, extending the service life of submersible sludge pumps and other heavy-duty systems. This material resilience is especially critical for operations in mining, wastewater, and industrial processing facilities, where chemical exposure and grit content are consistently high.

3. Seal and Bearing Protection Systems

Seals and bearings are among the most vulnerable parts of a pump, especially in continuous sludge transfer operations. Modern sludge pumps integrate double mechanical seals, oil-filled chambers, and labyrinth seals to prevent leakage and contamination. Advanced bearing protection systems shield internal components from fine solids, reducing the risk of premature failure and minimizing maintenance intervals.

4. Self-Priming Capability and Dry-Run Protection

A self-priming system allows a sludge pump to evacuate air from the suction line automatically, enabling faster startup and more reliable operation, especially in portable or intermittent-use scenarios. Dry-run protection, meanwhile, ensures the pump’s motor and seals are protected during temporary fluid loss. This is particularly valuable at remote sites where pumps operate unattended or where water levels fluctuate, such as in lagoons or dewatering pits using submersible sludge pumps.

5. Ease of Maintenance and Spare Part Availability

To minimize downtime, pumps must be conveniently maintained on-site. Modular structure, quick-release casings, and standard replacement components all help to simplify maintenance procedures. Access to local servicing and replacement parts improves operational efficiency by lowering turnaround times and reliance on offshore suppliers.

For projects with varying demands or short-term sludge management needs, sludge pump rental solutions offer a practical, cost-effective approach. Rental programs allow access to industrial-grade equipment, such as submersible sludge pumps and centrifugal systems, without long-term capital commitment. This flexibility ensures that operations can scale up or down based on project requirements, maintaining productivity without compromising reliability.

Additionally, sludge pump rental services give contractors and municipal operators the freedom to test different pump configurations before purchasing, ensuring they select equipment best suited for their flow rates and solids characteristics. In emergency applications, sludge pump rental provides immediate access to high-performance units, reducing downtime and keeping critical infrastructure operational. For seasonal operations, such as dredging, wastewater bypasses, or agricultural lagoon cleaning, a sludge pump rental arrangement helps reduce idle equipment costs while ensuring consistent access to high-efficiency pumps when needed.

How to Size and Select the Right Pump for High-Solids Waste

Accurate pump size is critical for effective, trouble-free sludge transfer. Undersized pumps can cause clogs and excessive wear, whereas oversized units waste energy and increase operating costs. A careful approach to sizing ensures the chosen pump meets both the hydraulic and physical requirements of the application.

1. Determine Flow Rate (Q) and Total Dynamic Head (TDH)

Start by defining the required flow rate —the amount of sludge to be moved per hour —and the total head against which the pump must operate. The total dynamic head (TDH) represents the combined effect of elevation lift, friction losses, and discharge pressure. It can be expressed using the formula:

TDH=Hstatic+Hfriction+HdischargeTDH = H_{static} + H_{friction} + H_{discharge}TDH=Hstatic+Hfriction+Hdischarge

Where:

- Hₛₜₐₜᵢc = Vertical distance the sludge must be lifted.

- Hₓᶠʳᶦcₜᶦₒₙ = Head loss due to pipe length, bends, and fittings.

- H_dᵢₛcₕₐᵣgₑ = Pressure required at the outlet

Accurate calculation of TDH ensures that the selected submersible sludge pump delivers sufficient power to maintain a steady flow without overloading the motor.

2. Account for Pipe Diameter and Friction Losses

The internal diameter and total length of the discharge pipe have a major impact on pump performance. Smaller diameters increase friction and head loss, necessitating more power. However, oversized pipes reduce flow velocity, enabling materials to settle and leading to clogs. Striking the appropriate balance ensures optimal flow speed and energy efficiency, especially in long-distance pumping applications.

3. Assess Solids Concentration and Power Requirements

The higher the solids concentration, the greater the torque and horsepower required. Dense slurries containing sand or silt require rugged, high-capacity sludge pumps with wear-resistant impellers and heavy-duty casings. It’s also important to check the pump’s performance curves and match the actual sludge density and viscosity to ensure the pump operates within its most efficient range.

4. Example: Sizing a Submersible Sludge Pump for a Construction Lagoon

Consider a lagoon where sludge depth varies and solids concentration fluctuates due to rainfall and sediment inflow. In this case, a submersible sludge pump is ideal because it operates directly in the fluid without suction lift issues. The operator calculates the static head (depth + discharge height) and friction losses through the discharge hose to determine the total head. Based on this, the correct motor size and impeller design can be selected for consistent flow and minimal downtime.

For organizations managing short-term or variable projects, sludge pump rental options offer an effective way to test different configurations before making a permanent investment. By renting multiple pump types —centrifugal, positive displacement, or submersible —operators can evaluate real-world performance under site-specific conditions, ensuring long-term value and reliability.

Many industrial and municipal operations also use sludge pump rental programs during maintenance or system upgrades, allowing them to maintain flow continuity while permanent systems are offline. This proactive strategy prevents costly interruptions, enhances equipment utilization, and supports efficient project management across diverse high-solid applications.

Finally, sludge pump rental provides procurement teams with flexibility when dealing with seasonal demand peaks or emergency dewatering needs, allowing them to access equipment quickly without incurring significant capital costs. This type ensures constant production, safety, and performance even in the most demanding sludge-handling conditions.

Reliable Pumping Solutions for High-Solid Waste Applications

Achieving dependable sludge handling starts with precision: matching sludge characteristics to the right pump type and accurately sizing the system. The correct sludge pump not only ensures continuous performance and efficient solids handling but also minimizes wear, energy consumption, and unplanned downtime.

Working with experienced professionals is equally important. Pumps for Jamaica provides expert engineering support to help organizations choose, size, and maintain the most effective sludge pumps for their specific operational and environmental requirements.

For temporary operations, emergency bypasses, or testing equipment before purchase, sludge pump rental remains a smart and flexible option. It allows teams to maintain productivity and reliability without major capital investment.Contact Pumps for Jamaica today for professional sludge pump selection, precise sizing guidance, or short-term sludge pump rental to keep your high-solid waste systems running efficiently.