Slurry pumps are engineered to handle some of the toughest pumping challenges in industrial operations. Unlike standard water pumps, slurry pumps are specifically designed to move fluids containing a high concentration of solids, ranging from fine particles to large abrasive materials. These pumps are essential in industries where transporting sludge, tailings, or slurry mixtures is part of the daily workflow.

In sectors such as mining, dredging, wastewater treatment, and heavy construction, the ability to reliably handle abrasive, viscous, and solid-laden fluids can significantly impact operational efficiency and safety. Slurry pumps provide the durability and performance needed to operate in extreme environments, minimizing frequent breakdowns and maintenance interruptions.

For many businesses, investing in permanent equipment may not always be practical, especially for short-term or project-based needs. That’s where slurry pump rental becomes a valuable solution. It allows operators to access high-performance equipment without the overhead of ownership, enabling faster deployment and cost-effective operations.

Working with trusted slurry pump suppliers ensures not only access to the right pump model but also expert support in sizing, installation, and maintenance. Whether you’re managing tailings in a mine or clearing sediment from a construction site, slurry pump rental options offer the flexibility to adapt to evolving project demands.

What is a Slurry Pump?

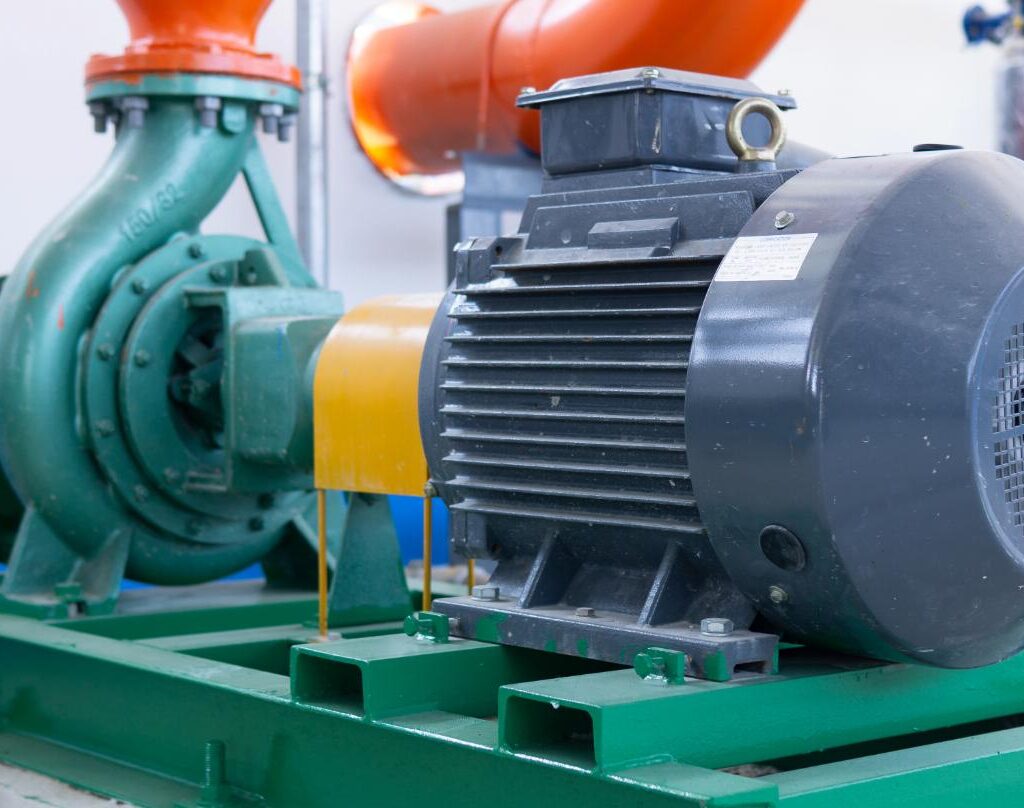

A slurry pump is a type of pump specifically designed for the transportation of slurry—a mixture of solid particles suspended in a liquid, typically water. These pumps are built to withstand the abrasion, corrosion, and heavy-duty requirements associated with moving slurries through pipelines. Their primary purpose is to handle fluids with high concentrations of solids, which can range from fine particles, such as sand and silt, to larger materials like rocks or coal fragments.

Unlike standard water pumps, slurry pumps are engineered with reinforced materials and specialized designs that make them suitable for handling abrasive and viscous fluids. Standard water pumps are typically intended for clean or lightly contaminated water and are not capable of withstanding the wear and tear caused by abrasive slurries. Key features of slurry pumps include heavy-duty impellers, durable casing materials (like rubber-lined or hardened metal), and mechanical seals designed to minimize leakage under extreme operating conditions.

The types of slurries these pumps handle are diverse. Common examples include mining tailings, drilling mud, dredging muck, cement mixtures, and sewage sludge. In each case, the consistency, density, and corrosiveness of the slurry vary, demanding tailored solutions provided by experienced slurry pump suppliers.

Slurry pumps are vital in numerous applications. In mining, they transport ore slurry from the excavation site to the processing plant. In dredging, they are used to remove sediment from riverbeds or harbors and transport it to disposal areas. In wastewater treatment plants, they help move thick sludge through various stages of filtration and processing. Construction projects may use slurry pumps to move bentonite slurry during tunnel boring or foundation drilling operations.

For projects that don’t require a permanent pump installation, slurry pump rental offers a practical and budget-friendly alternative. Renting allows businesses to access high-quality pumps on a short-term basis, making it ideal for emergencies, maintenance shutdowns, or temporary operations. Reputable slurry pump suppliers often provide rental services that include comprehensive support, covering pump selection, delivery, on-site installation, and maintenance assistance. By leveraging slurry pump rental solutions from trusted slurry pump suppliers, operators can maintain optimal productivity while avoiding large capital expenditures and the responsibilities of ongoing upkeep.

Key Components and How Slurry Pumps Work

Slurry pumps are robust machines made to handle abrasive, solid-laden fluids in some of the toughest industrial environments. Their effectiveness lies in a carefully engineered combination of key components, each playing a critical role in reliable slurry handling.

The impeller is the heart of the slurry pump. It rotates at high speed, generating centrifugal force that propels the slurry outward from the center and into the discharge pipe. Unlike standard impellers, those in slurry pumps are typically oversized and made from wear-resistant materials, such as high-chrome alloys or rubber, designed to handle large, abrasive particles.

The casing houses the impeller and directs the slurry flow, protecting the internal components. Slurry pump casings are typically thicker than those in water pumps and are often lined with replaceable, wear-resistant materials to extend their service life.

The shaft seal prevents slurry from leaking out of the pump housing where the shaft passes through. Depending on the application, slurry pumps may use mechanical seals, packing seals, or expeller seals, each of which is chosen to match the slurry’s characteristics and operating pressure.

Bearings support the rotating shaft and keep it aligned with the impeller. High-quality bearings are crucial, as misalignment can reduce efficiency and increase wear on other components.

The operation of most slurry pumps relies on centrifugal force. As the impeller spins, it imparts kinetic energy to the slurry, which is then converted into pressure energy. This process forces the slurry from the suction side of the pump to the discharge side, allowing it to move through pipelines, even over long distances or vertical lifts.

There are several types of slurry pumps, each designed to meet specific operational requirements. Centrifugal slurry pumps are the most commonly used and are ideal for continuously transporting slurry in demanding industries such as mining and dredging. Submersible slurry pumps, which operate while fully submerged, are perfect for deep pits, tanks, or sumps where conventional suction pumps fail. Horizontal slurry pumps are preferred for surface-level installations due to their ease of access and maintenance, while vertical slurry pumps excel in deep well or tank applications where floor space is limited. When considering a slurry pump rental, it’s crucial to match the pump type to your site’s needs. Leading slurry pump suppliers can help identify the right configuration and offer rental options tailored to both short-term and emergency use.

For short-term or project-specific needs, renting a slurry pump is a smart option. Many slurry pump suppliers offer rental programs that provide access to specialized pumps without long-term investment. Choosing reliable slurry pump suppliers ensures access to well-maintained rental equipment, technical expertise, and ongoing support throughout your rental period. With slurry pump rental, you get flexibility, performance, and peace of mind without compromising operational efficiency.

Types of Slurry Pumps and Selection Criteria

Slurry pumps come in various configurations, each tailored to specific operational needs. Understanding the different types and the factors that influence selection is critical for ensuring long-term performance and cost efficiency.

One key classification is orientation. Horizontal slurry pumps are the most common and are typically used in applications where the pump can be installed on a base plate and aligned with existing piping. In contrast, vertical slurry pumps are designed for sump or pit applications, where the pump needs to be submerged or partially submerged. These are ideal for confined spaces or deep-set slurry conditions.

The drive type is another important factor. Electric-driven slurry pumps are suitable for sites with stable power supplies and are known for energy efficiency and reliability. Hydraulic-driven pumps offer more flexibility in remote or mobile applications where electricity may not be readily available, especially in construction, dredging, or emergency dewatering.

Slurry pumps are also categorized by their application focus:

- Light-duty pumps are used for less abrasive slurries.

- Medium-duty pumps handle a balance of solids and fluid pressure.

- Heavy-duty pumps are built for extreme conditions with high solid content and strong abrasiveness, such as mining tailings or dredging operations.

When selecting the right pump, several performance criteria must be evaluated:

- Solids size and concentration: Larger or denser solids require pumps with reinforced impellers and higher clearances.

- Pump head and flow rate: These metrics determine how much slurry can be moved and how far it can be transported.

- Material of construction: Rubber-lined pumps resist chemical corrosion, while metal options offer superior resistance to abrasion.

Choosing the right equipment can be complex, which is why experienced slurry pump suppliers play a vital role. They assess your project’s unique requirements and recommend the best fit for you. Whether you’re purchasing or exploring slurry pump rental options, these suppliers offer essential insights to avoid under- or over-sizing issues.

For short-term jobs or temporary setups, renting a slurry pump provides flexibility without sacrificing quality. Reputable slurry pump suppliers offer rental units with full technical support, ensuring you have access to application-specific pumps exactly when and where you need them.

Benefits of Using the Right Slurry Pump

Selecting the correct slurry pump for your operation delivers far-reaching advantages that go beyond simply moving solids-laden fluids from one point to another. When you invest in the right solution—whether through direct purchase or a slurry pump rental- you unlock enhanced equipment longevity, improved operational efficiency, and greater overall system reliability. Trusted slurry pump suppliers play a key role in helping you choose the ideal pump configuration, ensuring maximum performance while minimizing downtime and maintenance costs.

One of the most immediate benefits is increased equipment lifespan. The right slurry pump, properly sized and constructed from the right materials, is built to withstand the specific abrasiveness and density of the slurry being transported. This prevents premature wear on components, such as impellers and seals, reducing the frequency and cost of replacements.

Operational efficiency and reduced downtime are also major gains. A well-matched pump runs within its optimal performance range, ensuring consistent flow rates and minimizing energy waste. Fewer breakdowns translate into less unplanned maintenance and more uptime for your critical operations, especially in time-sensitive industries like mining, construction, or dredging.

Using the correct slurry pump also leads to lower maintenance costs and improved safety. Pumps that aren’t struggling against misapplied conditions require fewer emergency interventions, and reduced component stress minimizes the risk of catastrophic failures that could pose hazards to workers.

For high-volume industrial applications, such as tailings management or dredging, the right slurry pump enhances throughput, allowing you to move more material in less time without compromising performance or damaging downstream systems.

Working with experienced slurry pump suppliers is essential to achieving these benefits. They provide expert guidance on pump selection, materials of construction, and system compatibility based on the specific properties of your slurry. They can also assist with slurry pump rental, a cost-effective solution for temporary projects or those requiring specialized equipment.

By collaborating with trusted slurry pump suppliers and leveraging slurry pump rental options when needed, you ensure your operation is equipped with the right tools to perform efficiently, safely, and reliably, regardless of the challenges your slurry presents.

Conclusion

Understanding how slurry pumps work and selecting the right type for your application is crucial to maximizing efficiency, safety, and equipment lifespan in any operation that handles abrasive or solid-laden fluids. Whether you’re managing mining tailings, dredging sediment, or processing wastewater sludge, the right pump, whether owned or sourced through a slurry pump rental, ensures consistent performance under demanding conditions. Partnering with experienced slurry pump suppliers can help you make informed decisions, offering expert guidance on pump selection, system integration, and flexible rental options tailored to your project needs.

Choosing an appropriate pump is not just a technical decision—it’s a strategic one. A poorly matched pump can lead to excessive wear, frequent downtime, and increased maintenance costs. On the other hand, the right pump, properly selected based on slurry composition, flow rate, and system layout, can enhance operational efficiency and protect surrounding infrastructure.

For temporary or project-based needs, renting a slurry pump provides a flexible and cost-effective solution without sacrificing quality. It allows operations to scale quickly while avoiding the overhead of owning permanent equipment.

To get the most out of your slurry pumping system, it’s essential to consult with experienced suppliers of slurry pumps. Their knowledge and technical support can help you identify the ideal solution, whether it’s installing a new system or renting a unit for a specific job.

Need expert advice or ready to explore slurry pump rental options? Contact our team today for personalized recommendations and dependable equipment that meets your unique operational demands.