Flooded Suction Pumps

Innovative Solutions for Handling Viscous and Abrasive Materials

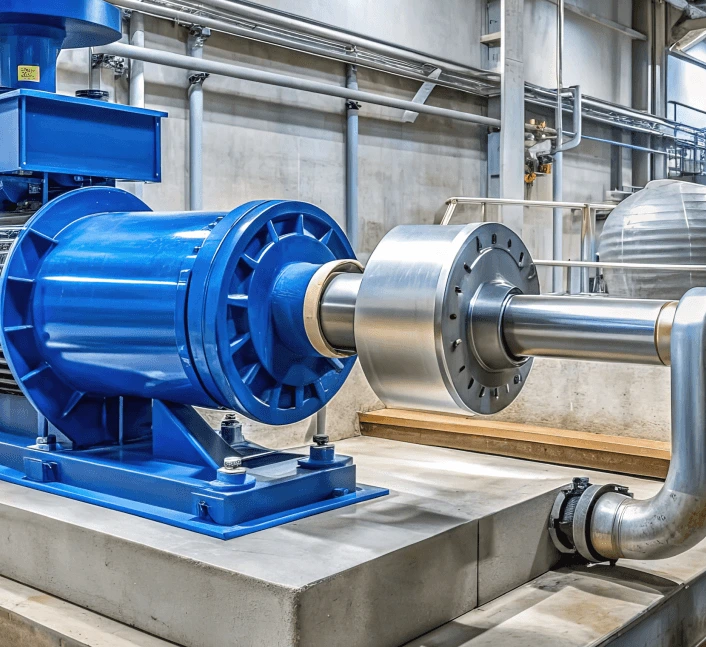

Pumps For Jamaica offers a comprehensive range of horizontal and vertical flooded suction industrial pumps specially designed to tackle the toughest material handling challenges. Our pumps excel at transporting highly viscous and abrasive substances such as sludge, pastes, and materials with high solid content while easily adapting to fluctuating fluid levels. Built to deliver durability and consistent performance, they are ideal for various industrial applications. These pumps are specifically engineered to manage dense slurries and complex fluid flows, ensuring they meet your precise needs and perform reliably under the most demanding conditions.

Exclusive Distributor of EDDY Pump in Jamaica

Pumps For Jamaica is proud to be the sole distributor of EDDY Pump in Jamaica, offering unparalleled access to top-tier pumping solutions. As the exclusive provider, we deliver EDDY Pump’s innovative technology, renowned for its efficiency in handling abrasive and viscous materials. Whether for industrial, dredging, or wastewater applications, our partnership with EDDY Pump ensures that customers in Jamaica receive the highest quality equipment backed by expert support and service.

Top-Quality Dredging Solutions for Tough Environments

At Pumps For Jamaica, we provide advanced, high-performance pumps designed to handle the toughest dredging challenges, including dense mud, sludge, pastes, and materials containing solids and abrasives. Our wide range of pumps is expertly crafted to deliver consistent performance even in the harshest conditions, minimizing downtime and ensuring smooth operations.

When it comes to reliability, Pumps For Jamaica is your trusted partner. We offer cutting-edge solutions tailored to meet the demands of the most complex projects. Our equipment is engineered for peak efficiency, even in extreme environments. You can count on Us for reliable and effective pumping solutions customized to your dredging needs.

Horizontal vs. Vertical Pumps: Choosing the Right Option

When deciding between horizontal and vertical slurry pumps, it’s essential to evaluate key factors such as fluid density, flow rate, pressure, transfer distance, power source, and environmental conditions like temperature, pH levels, and resistance to corrosion and erosion. Selecting pumps made from high-quality, durable materials, as found in our collection, ensures long-lasting reliability and strength.

Horizontal Flooded Suction Pumps

- Simplified installation and maintenance processes for easy setup and repairs.

- Equipped with larger impellers to boost flow rates.

- Typically require less Net Positive Suction Head (NPSH) compared to vertical models.

- Have a larger footprint, taking up more space.

Vertical Flooded Suction Pumps

- A compact design ideal for installations in tight spaces.

- Excellent for applications that require significant lifting power.

- Newer models allow for flexible deployment, including suspension via cables for deep insertion into materials.

- Maintenance and repairs can be more complex than horizontal pumps.

Our semi-automated dredge system is engineered for maximum efficiency while requiring only 650 square feet of operational space, eliminating the need for onboard personnel. 3 or 4 cables stabilize the system and utilize advanced electronic controls to manage winches, navigate the dredging path, adjust pump depth, and regulate RPM automatically. This cable-driven design allows for operation at depths of up to 100 feet, while the obstruction-free layout ensures continuous, smooth operation.

At Pumps For Jamaica, we are dedicated to delivering cutting-edge pumping solutions and innovative dredging systems. Our focus is on providing equipment that ensures optimal efficiency, durability, and outstanding performance. This commitment is at the core of our operations and guides our every decision.

Flooded Suction Pump Design and Performance

Paying attention to key factors like design, material quality, and operating requirements is essential when choosing a flooded suction pump. By considering these aspects, you can select a pump that ensures optimal performance, long-lasting durability, and cost-efficiency, making it the ideal solution for your unique application needs. Careful evaluation of these elements will help maximize operational effectiveness and reduce maintenance costs.

Search for a pump engineered explicitly for flooded suction applications, featuring robust construction to handle fluids and ensure reliable operation effectively.

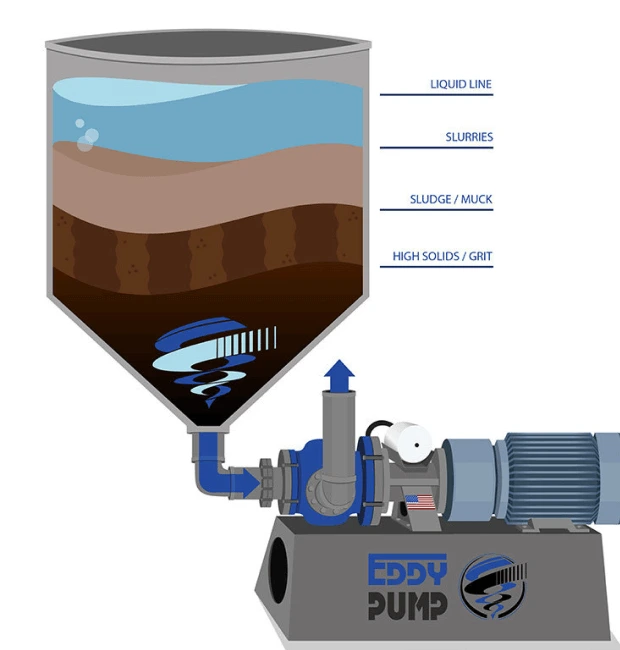

Flooded suction pumps are adept at managing fluids with high solids concentrations or slurry consistency. They are designed to efficiently transport and pump liquids containing particles, debris, or abrasive materials, making them ideal for challenging environments.

Engineered to allow the passage of solids without obstructions or blockages, flooded suction pumps minimize the need for frequent maintenance or repairs, enhancing operational efficiency.

These pumps operate more efficiently by reducing the risk of clogging, ensuring a consistent and steady flow. This improved efficiency translates to reduced downtime and increased productivity.

Constructed from durable materials and incorporating wear-resistant features, flooded suction pumps offer exceptional resistance to wear and tear, significantly extending their durability and lifespan.

Flooded suction pumps provide a cost-effective solution for handling slurries and challenging fluids. It’s crucial to consider the required flow rate for your application to ensure efficient fluid handling without overburdening the system.

Assess whether the pump can manage the necessary head pressure without compromising performance. Head pressure indicates the vertical distance the pump must lift the fluid, a critical factor for effective operation.

Ensure the pump’s fixtures are compatible with the type of fluid being pumped. Different water types and chemical compositions may require specific materials, such as stainless steel, cast iron, or high-strength polyethylene, to prevent corrosion and ensure longevity.

Consider the pump motor’s rated power and efficiency. Higher-power motors may be necessary to achieve higher flow rates or pump thicker fluids, ensuring the pump operates within its optimal performance range.

Look for pump models with robust sealing options to prevent leaks and maintain optimal performance. Reliable seals are crucial for maintaining the pump’s integrity and the safety of the operation.

Evaluate the ease of installation and maintenance requirements of the pump. Consider factors such as service accessibility, availability of spare parts, and the simplicity of routine maintenance procedures.

Ensure the pump includes advanced security features such as overload protection, temperature sensors, and guards. These features protect the pump from damage and prolong its operational life.

Research the pump manufacturer’s reputation and relationship with consumers. Opt for a company that produces high-quality, reliable pumps and offers excellent customer service and support.

Get to know our pump models

Model | Diameter | GPM Flow | Head |

HD1K | 1.5 x 1 Inch | 1 - 200 | up to 170 feet |

HD 2000 | 3 x 3 inches | 50 - 390 | up to 90 feet |

HH 2000 | 3 x 3 inches | 100 - 600 | up to 350 feet |

HD 3000 | 4 x 3 inches | 100 - 780 | up to 130 feet |

HD 4000 | 6 x 4 inches | 250 - 2100 | up to 160 feet |

HD 5000 | 5 x 5 inches | 400 - 1800 | up to 225 feet |

HD 5000 | 6 x 5 inches | 400 - 1800 | up to 225 feet |

HD 6000 | 8 x 6 inches | 450 - 2500 | up to 200 feet |

HD 8000 | 10 x 8 inches | 1400 - 3600 | up to 230 feet |

HDX 10000 | 12 x 10 inches | 1600 - 5000 | up to 240 feet |

HD 12000 | 14 x 12 inches | 2600 - 7300 | up to 180 feet |

Advantages Across Various Applications

Exceptional Solid Handling

Flooded suction pumps excel in handling fluids with high solids content, making them ideal for applications involving particulate-heavy liquids. Their sturdy construction ensures efficient transportation of even the most challenging materials.

Minimized Clogging Risks

With an advanced design that minimizes the chance of obstructions, these pumps significantly reduce the need for frequent maintenance and repairs, leading to smoother, more reliable operation.

Superior Durability

Built from durable materials and designed to withstand wear and tear, these pumps deliver long-lasting performance, even in harsh environments. Their durability makes them a dependable choice for demanding applications.

Enhanced Operational Efficiency

Flooded suction pumps maintain a consistent flow rate, boosting overall efficiency and minimizing downtime. This results in increased productivity across a wide range of industrial applications.

Cost-Effective Fluid Management

Flooded suction pumps offer an economical solution for handling slurries and other challenging fluids. Their efficiency and affordability make them a top choice for businesses looking to manage costs without sacrificing performance.

Our Dredging Equipment

Submersible Slurry Pumps

Submersible pumps are designed to be installed directly into the liquid they are meant to pump, eliminating the need for priming. With the motor fully submerged, these pumps offer easy installation and operation, making them an efficient and reliable addition to your pumping system. Their straightforward design ensures confidence in consistent performance.

Self-Priming Pumps

Self-priming pumps are positioned above the water and use a suction hose to draw in fluids, functioning much like a large wet-dry vacuum. Their portability and towing capabilities make them a versatile choice for a wide range of applications, providing flexibility and ease of use in various environments.